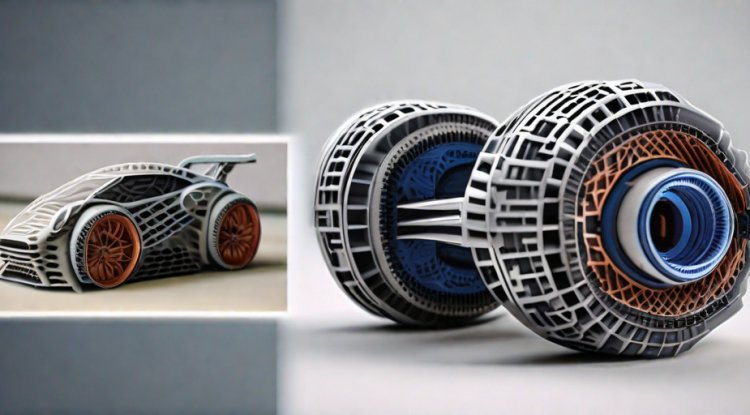

The Impacts of AI on the Evolution of 3D Printing Industry

This article explores how artificial intelligence (AI) is transforming the landscape of the 3D printing industry, revolutionizing it in terms of speed, efficiency, cost reduction, and customization. It highlights recent advancements, challenges, and future prospects

The integrated emergence of artificial intelligence (AI) within the realm of 3D printing has completely altered the course of this rapidly growing industry. AI's integration is not solely confined to design, but also covers the entire cycle, from the design process to the manufacturing stage, management, and even maintenance. In this article, we'll examine the impacts of AI on various aspects of the 3D printing industry, focusing on its advantages and challenges.

First and foremost, AI's introduction has propelled the 3D printing industry into a new paradigm, largely due to its ability to significantly improve time and resource efficiency. By employing machine learning algorithms, AI can boost the speed of the entire process, allowing for faster prototyping and production. This aspect becomes especially pertinent in industries that require rapid innovation and high-speed production, such as automotive and aerospace. This includes predictive maintenance that can help prevent unforeseen downtime, saving costs and providing a more reliable and sustainable process.

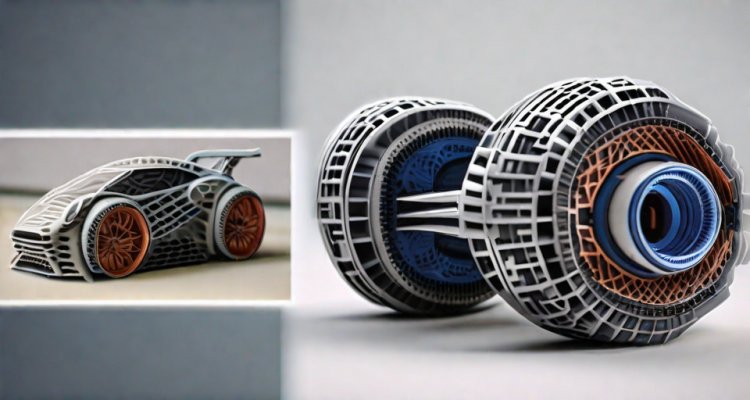

Within the realm of design, AI has demonstrated great promise in mimicking human intelligence and creativity. For instance, algorithms can help generate bespoke designs based on customer requirements or incorporate specific design features without human intervention. This method results in customized products that cater to individual needs while taking into consideration environmental requirements. The ability to more accurately predict design and construction issues prior to actual fabrication also ensures a higher quality output and minimizes waste.

AI has significantly reduced the turnaround time in the 3D printing sector, catering to the ever-increasing demand for speedy prototyping and manufacturing. Consider the example of generative design, where AI algorithms learn from human-created designs and replicate them to create optimal solutions catering to specific requirements. This enhances the efficiency and adaptability of the process, rendering it an indispensable tool for both designers and manufacturers.

AI applications in 3D printing play a significant role in cost reduction by promoting efficient resource utilization and reducing material consumption. Through continuous monitoring and machine learning, AI optimizes the printing process, improving material usage. Moreover, AI-assisted maintenance enables the early detection of potential issues, preventing costly repairs or even machinery downtime. This proactive approach to maintenance helps manufacturers and suppliers save money and ensure long-term financial stability.

However, the AI disruption is not without its challenges. As AI continues to evolve and infiltrate the 3D printing market, a few challenges emerge that complicate its widespread adoption. The primary concern is data privacy - the vast quantity of information required by AI machine learning models raises pragmatic concerns about the security of user data. Furthermore, the lack of universal AI standards could result in interoperability headaches, making adoption and integration laborious for manufacturers. These and similar challenges, if not duly addressed, may potentially hamper its widespread adoption and growth.

The prospects of AI within the 3D printing space look promising given its demonstrated performance, even in the face of challenges. The seemingly endless potential for tailored products and innovative design solutions can open doors to a multitude of new industries and applications. As AI tools continue to evolve, we can anticipate further paradigm shifts and disruptions in the 3D printing industry, with novel solutions emerging to enhance its efficiency, customization, and cost reduction capabilities. The constantly evolving nature of the technology will undoubtedly reshape the landscape of this sector, creating a more agile, efficient, and more responsive manufacturing ecosystem.

Overall, the advent of AI within the 3D printing sector has become a game changer, with its potential to amplify speed, efficiency, cost reduction, and customization. However, it's crucial to track and resolve the numerous obstacles impeding its adoption, ensuring a smoother integration that guarantees maximum benefit to stakeholders and optimizes the industry's functionality. This paves the way for a future where 3D printing business encompasses smarter, more resilient and engaged processes, resulting in thriving businesses, enhanced customer experiences, and eco-friendly processes.

What's Your Reaction?